google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic spray photoresist -- semiconductor wafer -- YMUS ultrasonic spray

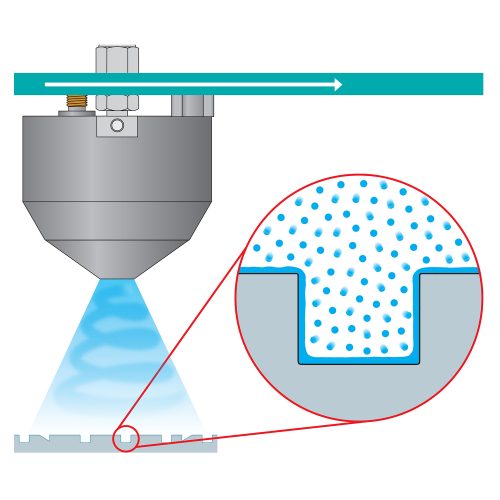

Direct spray photoresist coatings have been performed on MEMS wafers and other 3D microstructures, with significant research on the advantages of spray deposition into deep well (high) terrain. Compared with traditional spin coatings, ultrasonic sprayed photoresist coatings have advantages in deposition of more uniform coatings, especially in the top part of the sidewall of high aspect ratio grooves and V-shaped grooves. The centrifugal spin makes deposition of uniform films along the sidewall impossible to deposit too much photoresist at the bottom of the cavity.

Ultrasonic spraying is a simple, economical and repeatable photolithographic silicon coating process. YMUS Ultrasonic Spray system allows precise control of flow, coating speed and deposition using advanced layering technology. Low-speed spray forming defines atomizing spray in a precise, controlled pattern that avoids overspraying while producing very thin, even layers. The use of ultrasonic spraying technology proved to be a reliable and effective way to deposit the photoresist onto 3D microstructures, thereby reducing equipment failure due to excessive exposure of the metal to the etching agent.

Benefits of ultrasonic nozzles in direct spraying photoresist processes include:

● Uniform film covering a variety of surface contours

● Can be coated height width ratio groove, good uniformity

● Non-clogging atomizing spray

● It can deposit thin single micron layers with high uniformity

The YMUS Ultrasonic Nozzle series uses high-frequency vibrations to produce a mathematically defined soft mist of droplets. Nozzle clogging is eliminated because there is no pressure to produce the spray, and the droplets are distributed in very narrow sizes, further contributing to the uniformity of the deposit layer.