google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic spraying to prepare electrodes for efficient and stable CO₂ electrolysis - solid oxide electrolysis cell

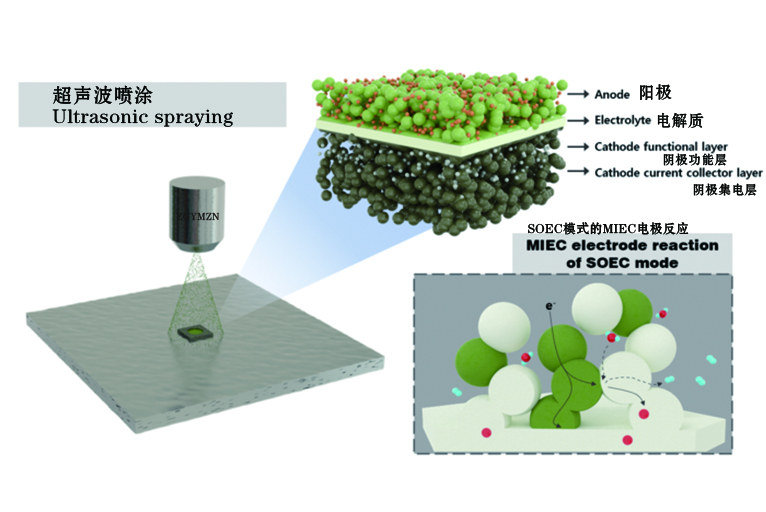

Achieving carbon neutrality goals requires innovative CO₂ emission reduction technologies, and solid oxide electrolyzers (SOECs) have attracted much attention due to their ability to efficiently convert CO₂ to O₂, fuels, and chemicals. However, Ni-based fuel electrodes are redox unstable under direct CO₂ electrolysis conditions, which severely limits their commercial application. In addition, traditional electrode preparation methods are time-consuming, complex, and costly, and new materials and processes are urgently needed to improve the performance and manufacturability of SOECs. Recently, a new all-ceramic fuel electrode (La0.75Sr0.25)0.97Cr0.5Mn0.5O3@Ce0.6Mn0.3Fe0.1O2 was proposed. LSCM nano-CMF was prepared in one step using ultrasonic spraying technology. Ultrasonic spraying technology can quickly form uniform electrodes with nanostructures, significantly simplifying the traditional multi-step impregnation preparation process. Studies have shown that this nanocatalyst is rich in oxygen vacancies and forms a unique synergistic catalytic effect at the perovskite/fluorite phase interface, which greatly improves the CO₂ adsorption capacity and electrochemical activity.

The optimized LSCM@nano-CMF fuel electrode prepared by ultrasonic spraying exhibits excellent electrochemical performance and stability in SOEC. Compared with the LSCM/CMF composite electrode prepared by conventional ball milling, the CO₂ electrolysis current density of the LSCM@nano-CMF fuel electrode at 850°C and 1.5 V is as high as 3.01 A cm¯², far exceeding 2.56 A cm¯². The addition of nanocatalysts significantly increases the active sites, while the perovskite/fluorite interface enhances the catalytic activity.

Advantages of ultrasonic spraying:

1. Uniformity: Ultrasonic spraying technology can produce uniformly distributed coatings, making the coatings have better density and consistency, which is conducive to improving the performance and stability of SOEC.

2. Precision: Ultrasonic spraying technology can achieve precisely controlled coating thickness, which is crucial for the performance and stability of SOEC.

3. Improve efficiency: Ultrasonic spraying technology can achieve high-speed spraying, improve production efficiency and reduce preparation costs.

4. Applicability: Ultrasonic spraying technology is suitable for SOEC substrates and components of various complex shapes and sizes, and has high adaptability.

As SOEC technology achieves tighter value chain integration with intermittent renewable energy sources (wind, solar, etc.), it will gain the boost it needs to achieve its cost-competitiveness goals. Now is the right time as more economies align their policies to support efficient energy conversion technologies such as SOECs to achieve their net zero emissions goals.