google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Flexible perovskite solar cells, from materials to applications - ultrasonic spraying

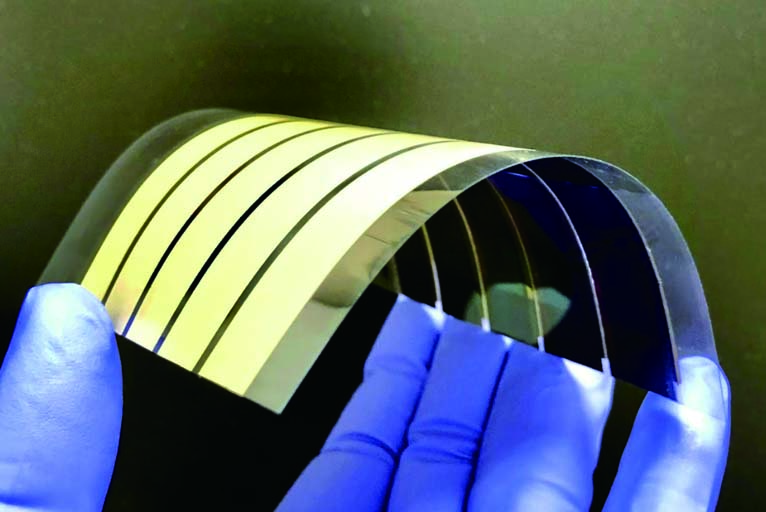

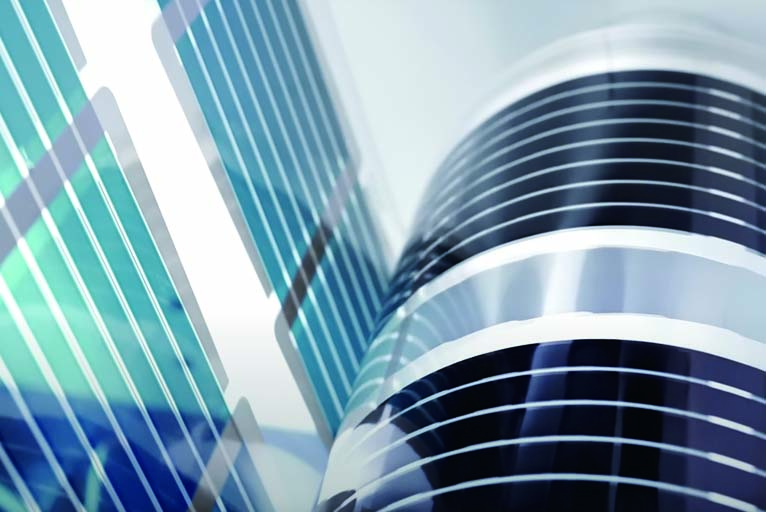

Perovskite solar cells (PSCs) have attracted extensive attention from photovoltaic scientists in recent years due to their high efficiency, low cost and solution processability. Due to the fascinating optoelectronic properties of perovskite materials, such as high light absorption coefficient, ideal/tunable band gap and long charge diffusion length, the highest certified power conversion efficiency (PCE) of PSCs based on rigid glass substrates has been improved to 25.5%. In addition to excellent optoelectronic performance, the inherent mechanical flexibility and low-temperature solution processability of perovskites make it possible to realize flexible perovskite solar cells (FPSCs). FPSCs are expected to find applications in unmanned systems, smart integrated buildings, wearable and portable electronics, and self-powered bioelectronic devices. More importantly, the fabrication of FPSCs is compatible with roll-to-roll (R2R) printing processes, which will enable large-scale production and promote the commercialization of perovskite photovoltaic technology. Therefore, the development of FPSCs is of great significance for the practical application of PSCs.

In addition to efficiency, the mechanical flexibility of FPSCs is another important issue. Deformable and stretchable FPSCs can be achieved by employing flexible substrates with high bending durability. Using shape-restorable polymers as flexible substrates, highly deformable FPSCs were successfully fabricated.

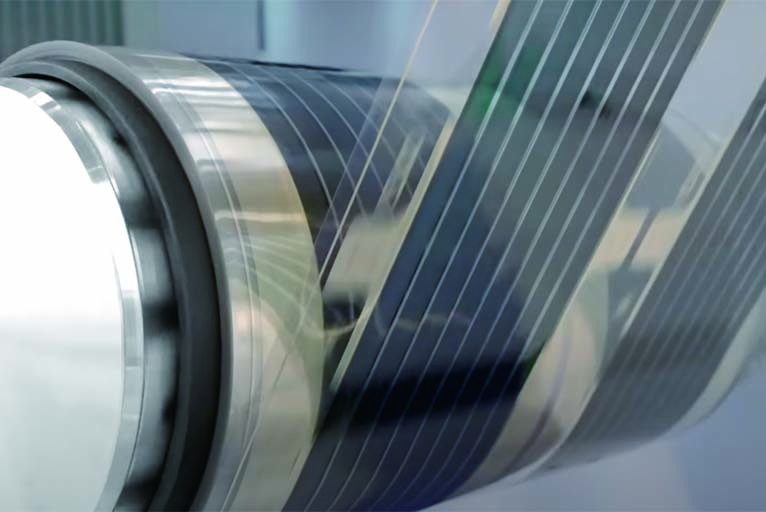

Low cost, high yield and large-scale manufacturing are prerequisites for the commercialization of perovskite photovoltaic technology. R2R coating is an effective way to meet the requirements. FPSC is prepared by ultrasonic spraying R2R coating method, and the efficiency of the prepared device is significantly improved.

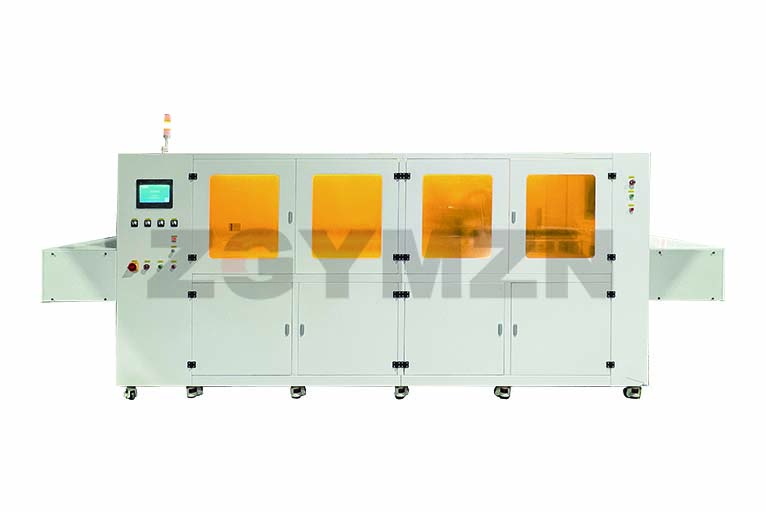

Shanghai Yangmi roll-to-roll ultrasonic precision spraying equipment adopts ultrasonic nozzle technology, automatic reeling and unreeling, online substrate heating function, realizes spraying and drying, and improves production efficiency. It can provide uniform and efficient thin film spraying and spray pyrolysis, and the thinnest film thickness can reach tens of nanometers. It is suitable for the preparation of various nano and submicron films such as flexible films, thin film solar cells, fuel cells, PET films, non-woven fabrics, fabric functional coatings, carbon fibers, glass fibers, etc.