google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Vacuum adsorption heating platform provides flexibility for ultrasonic spraying -- film coating -- YMUS Ultrasonic spraying

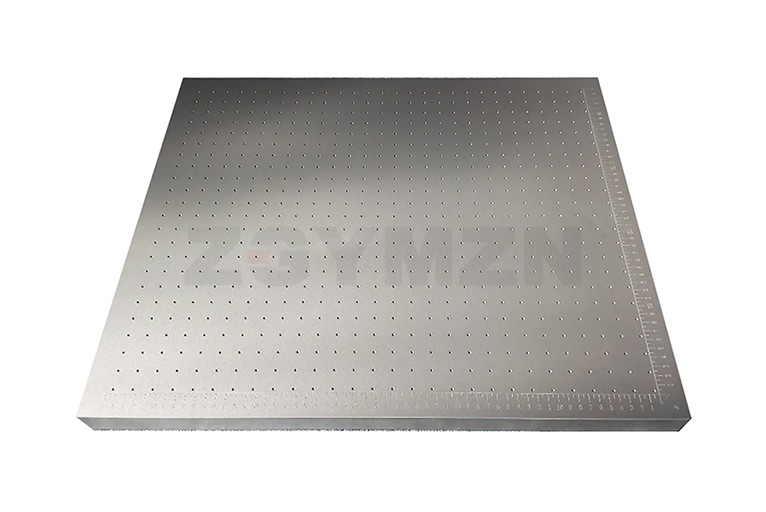

YMUS Ultrasonic Spraying Machine can be equipped with a vacuum adsorption heating platform for thin substrate, wafer, foil and film coating applications, where control of the substrate is enhanced to achieve desired coating thickness and uniformity. The adsorption heating platform can be programmed to heat the substrate to 150℃-500℃. Vacuum adsorption heating platform has aluminum alloy, titanium alloy, silicon carbide and other materials to choose from, can meet various requirements.

Note:Vacuum adsorption heating platform

Flexible and highly configurable spraying systems for semiconductor, fuel cell and microelectronics production and development applications. YMUS Ultrasonic nozzle technology provides up to 95% raw material utilization.

Note: YMUS Ultrasonic nozzle series