google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation process of membrane electrode catalyst - Hydrogen energy, hydrogen production from electrolytic water -YMUS ultrasonic spraying

Coated catalysts have the advantages of both high strength and high reactivity, and have been used in many catalytic reactions such as gas purification and selective catalytic oxidation. Coating is the key process in the preparation of coated catalyst, which has an important effect on the performance of catalyst. The characteristics and research progress of YMUS ultrasonic spray coating technology in the aspects of catalyst support, molding additives and processes.

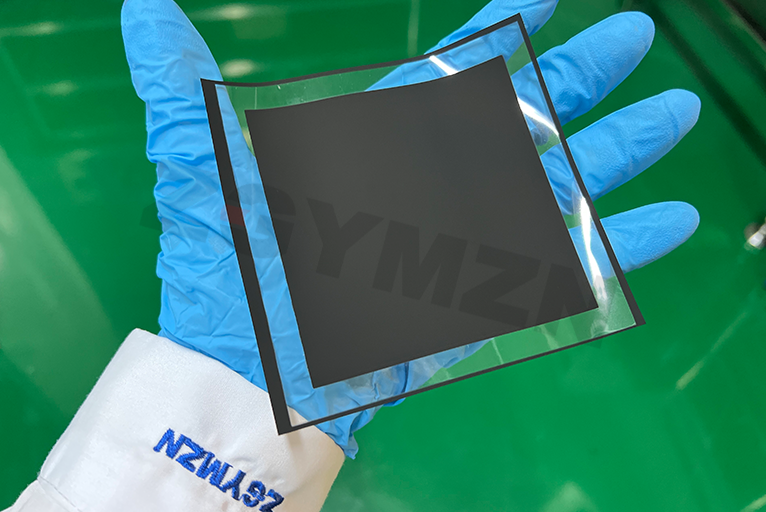

Membrane electrode, as the core component of electrochemical device, is one of the keys to the research and development of hydrogen fuel cell, hydrogen production by electrolytic water, electrochemical synthesis and other technologies. The structure design and preparation process of membrane electrode have great influence on the performance of electrochemical devices. At present, in the laboratory membrane electrode research, ultrasonic spraying technology is widely used to achieve uniform coating of catalysts. YMUS ultrasonic spraying equipment plays a key role in the development and preparation of fuel cell membrane electrodes.

◆ High controllability

Precise control of atomization flow, low flow continuous spray, spray shape is easy to control and shape (increase spray robot arm), suitable for industrial fields. Through the combination, the atomization volume can meet any requirements of the user.

◆ Wide application

Ultrasonic spraying equipment is mainly used in fuel cells, thin film photovoltaic cells, thin film solar coatings, perovskite solar cells, solar cells, graphene coating, silicon photovoltaic cells, glass coating, electronic circuits and other industries. Nozzle can be applied to a variety of solutions, even sewage, chemical liquids, low viscosity oil mucus can also be atomized spray.

◆ Saving materials and environmental protection

The spray impact force is small, will not cause liquid splash, can reduce the waste of raw materials and air pollution caused by reverse spray. The coating utilization rate of ultrasonic spraying is more than 4 times that of traditional two-fluid spraying.