google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Application of PTFE coating on medical devices - Coating preparation - YMUS ultrasonic spraying

Polytetrafluoroethylene (PTFE) coating is widely used in medical devices. PTFE is a low-friction, chemically resistant and high-temperature stable material with excellent non-adhesion and wear resistance, making it suitable for use in medical devices where friction needs to be reduced and adhesion prevented.

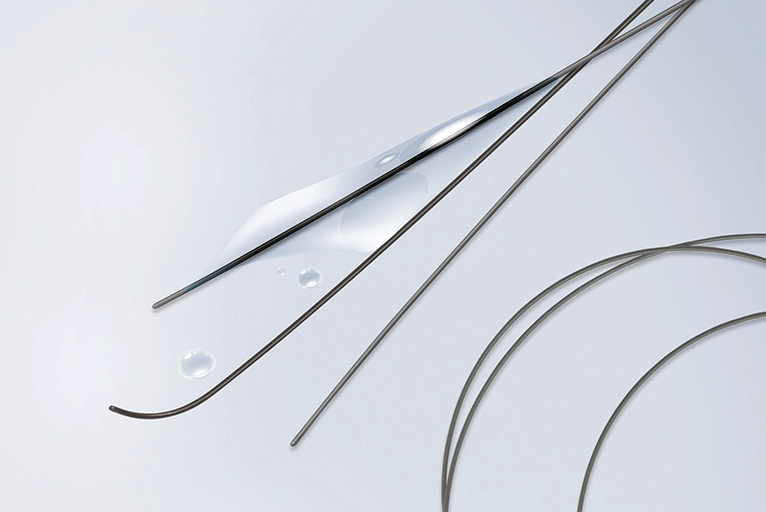

Organic coatings are widely used in medical catheters, guide wires and orthopaedic wires in microtrauma (or intravascular) interventional therapy. The outermost coating of the catheter is mostly made of polyethylene, which determines a catheter's shape, hardness and friction with the blood vessel lining. The inner layer is mostly PTFE coated, and the hydrophobicity of PTFE is used to reduce the friction resistance of the guide wire, balloon, stent and the guiding tube cavity, and prevent thrombosis. The PTFE-coated interventional guide wire at the proximal push rod segment can enhance the passage ability of the guide wire in the human lumen, suitable for passing through calcification, twisted and blocked lesions. Because PTFE coating has good biocompatibility and corrosion resistance, its application on the surface of dental orthopedic wire can significantly stabilize the performance of dental orthopedic wire and increase its service time.

Common applications using PTFE coatings in medical devices:

1, Surgical instruments: PTFE coating can be applied to the surface of surgical instruments, such as surgical blades, pliers and tweezers, to reduce friction and adhesion, improve the smoothness and efficiency of surgical operations.

2, Medical catheter: PTFE coating can be used for various medical catheters, such as catheters, hemodialysis catheters and intravascular stents, etc., to reduce blood clots and adhesion and prevent blood vessel blockage.

3. Dispensers and syringes: PTFE coating can be used on pistons and needles of dispensers and syringes to reduce friction and improve operation smoothness and accuracy.

4, Medical suture: PTFE coating can be applied to medical suture to reduce friction and improve puncture smoothness.

5, Medical air bag: PTFE coating can be used for medical air bags, such as lung dilators and balloon catheters, to reduce friction and adhesion, improve the expansion capacity and stability of the air bag.

6. Guide wire/spindle: PTFE-coated medical device guide wire is mainly made of stainless steel. In the process of use, the guide wire needs low friction performance, good adhesion of the coating and high dimensional accuracy of the guide wire. The cross section of stainless steel wire can be round, can also be non-circular, can be a single beam, can also be multiple.

The application of PTFE coatings in medical devices can improve device performance, reduce adhesion and friction, and improve patient comfort and the smoothness of surgical procedures. However, the specific application needs to be determined according to different devices and needs, while the safety and quality of the coating is also very important, and the relevant standards and regulations need to be followed when using.

Ultrasonic sprayed PTFE solution is used to form a thin and uniform PTFE coating on the surface of the guide wire. This coating can provide non-adhesion, wear resistance and good chemical stability of the guide wire, thereby improving the performance and service life of the guide wire.