google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Characteristics and Application of Teflon Material —— A New Material ——YMUS Ultrasonic Spraying

Teflon coating is the originator of non-stick coating, which combines heat resistance, chemical inertia, excellent insulation stability and low friction, and has comprehensive advantages that other coatings can't compete with. Teflon material has the characteristics of acid resistance, alkali resistance and resistance to various organic solvents, and is almost insoluble in all solvents. At the same time, it also has the characteristics of high temperature resistance, and the friction coefficient is extremely low, which is the smoothest surface in the world. Its friction force is only equivalent to the friction force between ice, which is listed in the Guinness Book of World Records.

Application field:

1. Coating of medical devices: Teflon has excellent chemical corrosion resistance and low surface energy, which can be applied to the coating of medical devices, providing excellent durability and good chemical stability.

2. Surface coating of medical equipment: Ultrasonic spraying Teflon solution can be used to coat the surface of medical equipment to prevent the adhesion of pollutants and improve the corrosion resistance and easy cleaning of the equipment.

3. Medical anti-adhesion coating: Teflon has excellent non-adhesion performance, which can be applied to the coating of medical instruments such as surgical tools and implants to reduce adhesion and improve the service life and sanitary performance of the instruments.

Advantages advantages:

1. Non-adhesive performance: Teflon has excellent non-adhesive performance, which can reduce the adhesion of biological substances such as blood and protein, reduce the risk of infection, and facilitate cleaning and disinfection. This feature is very important for surgical instruments, implants and other medical devices.

2. Chemical corrosion resistance: Teflon has excellent chemical corrosion resistance and good tolerance to common corrosive media such as acid and alkali. This enables Teflon coating to resist the corrosion of chemicals such as drugs and disinfectants in medical devices.

3. Temperature stability: Teflon has high thermal stability at high temperature, can withstand high-temperature disinfection and sterilization, and will not lose its physical properties, ensuring the reliability and durability of medical devices.

4. Biocompatibility: Teflon has good compatibility with human tissues and liquids, and has excellent biocompatibility, and will not produce toxic and irritating reactions to the human body.

5. Wear resistance and durability: Teflon has good wear resistance, which can provide the durability and long-term performance stability of medical devices and reduce the wear and damage of devices.

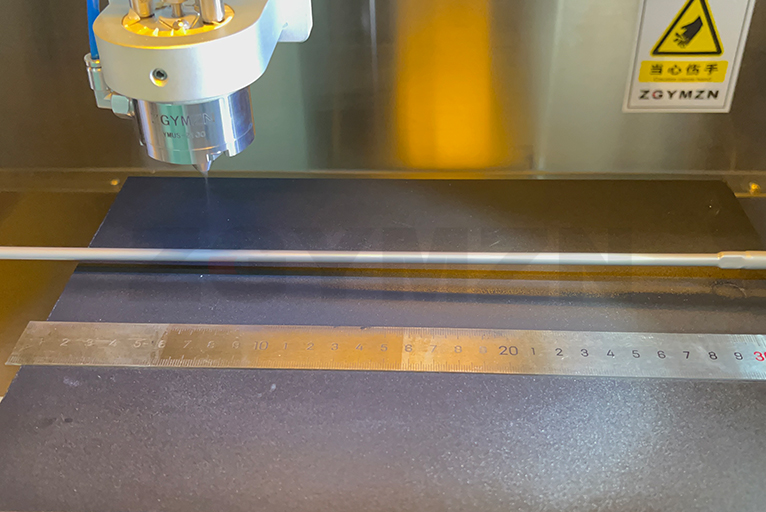

YMUS ultrasonic spraying Teflon solution is used to coat medical devices, it is necessary to ensure the quality, thickness and uniformity of the coating to ensure the stability and reliability of its performance. Ultrasonic spraying has many advantages in the field of drugs and medical devices, which can help improve the controlled release effect of drugs, improve the performance and function of medical devices, and realize high-quality coating preparation. The advantages of this technology make it widely concerned and applied in the medical field.