google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

New material hydrophobic and oleophobic nano-coating-surface treatment-YMUS ultrasonic spraying

There are all kinds of substrate surfaces in daily life, such as metal surface, glass surface, leather surface, stone surface, plastic surface, ceramic surface, wood surface, electric appliance shell surface ...

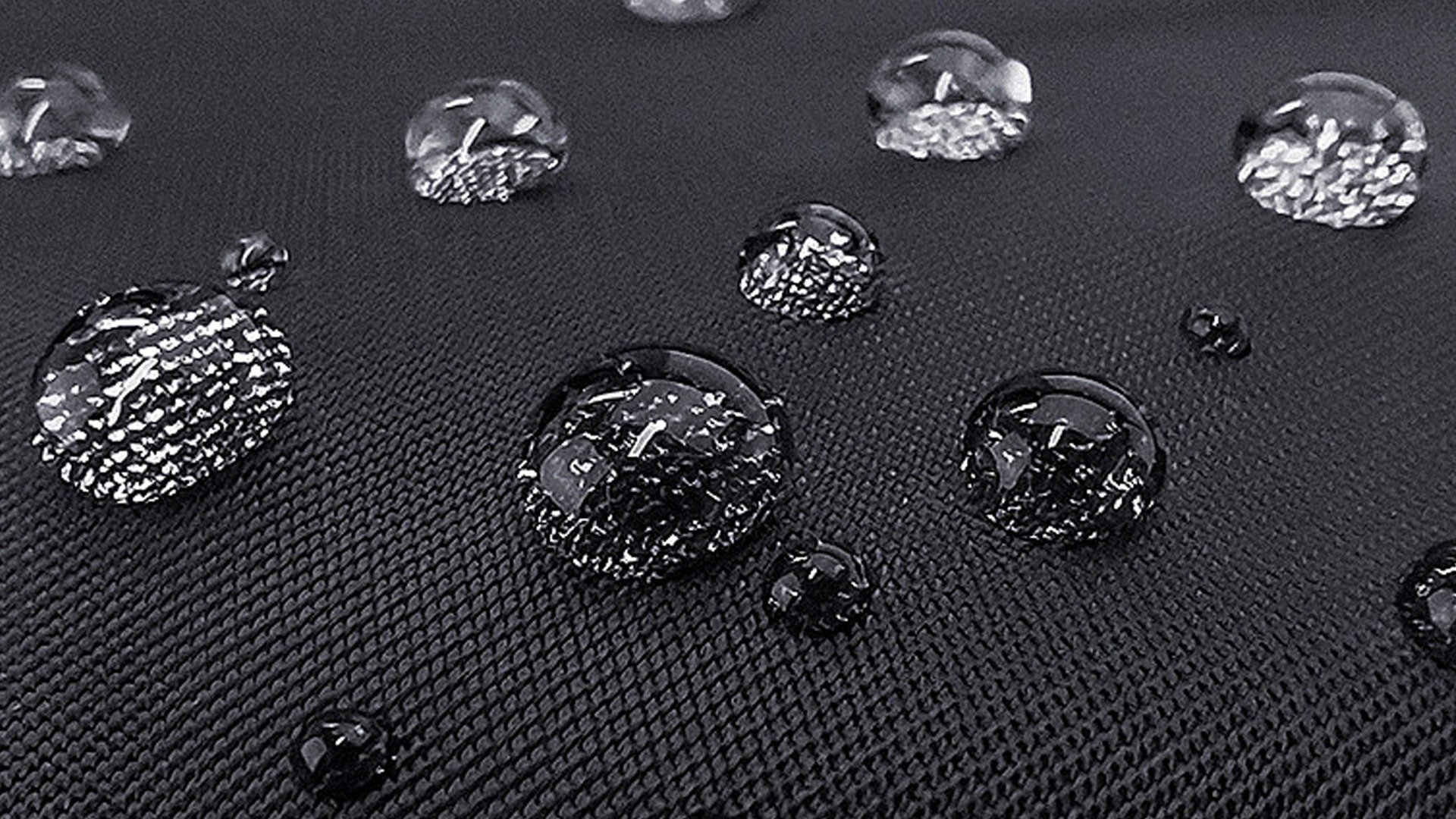

In practical application, these surfaces will encounter all kinds of dirt, such as mud, ash, oil stains and their mixtures. Water drops form a sphere on the surface, which can't adhere to the surface of the substrate, thus achieving ultra-clean and ultra-anti-pollution effects.

Nano-coating is a kind of thin film coating, which is composed of nano-particles, and its thickness is usually between several nanometers and several tens of microns. These nanoparticles can be metals, ceramics, polymers or other materials with special chemical, physical or optical properties. The formation of nano-coating is mainly prepared by ultrasonic atomization solution.

Ultrasonic spraying hydrophobic and oleophobic coating:

1. Efficient and fast: Ultrasonic spraying technology is simple, fast and efficient, and can spray hydrophobic and oleophobic coatings evenly in a short time.

2. Uniformity: Ultrasonic spraying technology can generate high-frequency acoustic vibration. When liquid particles are evenly sprayed on the surface, a uniform and compact coating can be obtained, which improves the hydrophobic and oleophobic effect.

3. Controllability: ultrasonic vibration disperses the coating particles, which can control the size and distribution of the particles and realize the precise regulation of the coating performance.

Hydrophobic and oleophobic application fields:

1. Ship and marine engineering: Ultrasonic spraying hydrophobic and oleophobic coating can be applied to ship and marine engineering to reduce the adhesion of water or oil, improve the anticorrosion performance of hull and marine facilities, reduce friction resistance and improve navigation efficiency.

2. Cars and vehicles: Ultrasonic spraying hydrophobic and oleophobic coating can be applied to the surfaces of vehicles such as cars and airplanes to reduce the adhesion of water drops and oil stains and improve the surface cleanliness and anti-pollution ability of vehicles.

3. Pharmaceutical and food industries: In pharmaceutical and food production, ultrasonic spraying hydrophobic and oleophobic coatings can be applied to the inner walls of pipelines and containers to reduce adhesion and improve production efficiency and cleanliness.

4. Building and building materials field: The application of ultrasonic spraying hydrophobic and oleophobic coating on the exterior wall of building and the surface of building materials can improve the weather resistance of materials, prevent the erosion of water and other pollutants, and prolong the service life of materials.

The effect and stability of YMUS ultrasonic spraying hydrophobic and oleophobic coating are also affected by many factors, such as the selection of coating materials, surface treatment and spraying process parameters, which need to be optimized and adjusted according to the requirements of specific applications.