google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Application of ultrasonic spraying -- film preparation -- YMUS Ultrasonic spraying

Ⅰ. Ultrasonic spraying application

Ultrasonic spraying plane substrate is glass, film battery, touch screen, fuel cell, nanomaterials and other production research and development of spraying equipment, with high spraying efficiency, low flow rate (controllable), uniform spraying layer, small atomized particles, online heating and other advantages. Compared with traditional spraying methods such as high pressure spraying, ultrasonic spraying equipment can control the speed and flow of spraying, and there will be no waste phenomenon such as sputtering in the spraying process. The solution utilization rate is more than 95%, reducing production costs and environmental pollution.

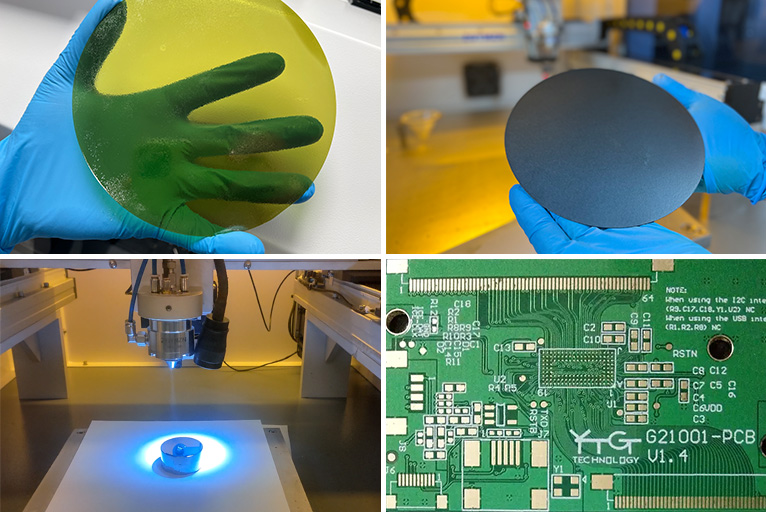

1. Electronic products (semiconductor, flux, precision electronics, etc.)

Because ultrasonic spraying has the advantages of precise and controllable spraying flow rate, thin and uniform coating, controllable spraying range and so on, it is very suitable for spraying electronic products, and is increasingly used in research and development and production. Ultrasonic spraying technology can be used to deposit uniform coatings on substrates of any width. Ultrasonic spraying technology enables the manufacture of these very thin coatings with extremely high uniformity, achieving very precise and repeatable results to improve product functionality.

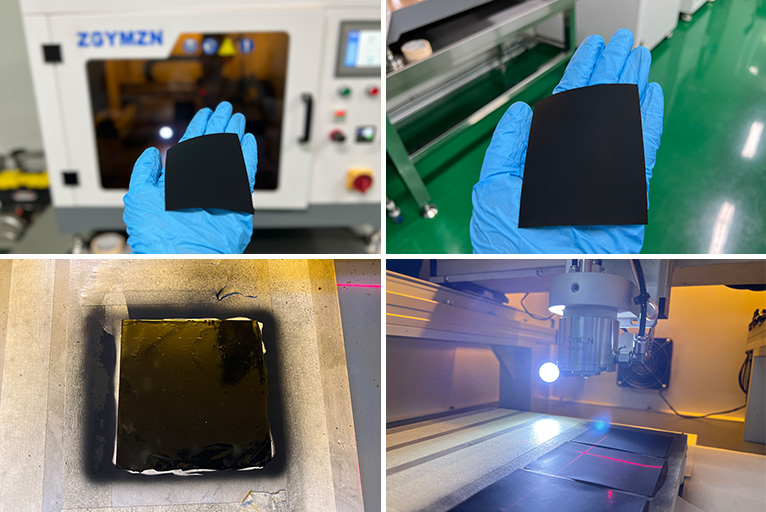

2. New energy (photovoltaic cells, fuel cells, thin film solar energy, etc.)

Ultrasonic spraying is very suitable for deposition of solar cells, fuel cells, silicon cell coatings, and is increasingly used in the development and production of spraying processes. Ultrasonic spraying technology can be used to deposit uniform and extremely thin coatings on substrates of any width. Ultrasonic spraying technology enables the production of very thin coatings with extremely high uniformity, resulting in improved electron conversion and transportation.

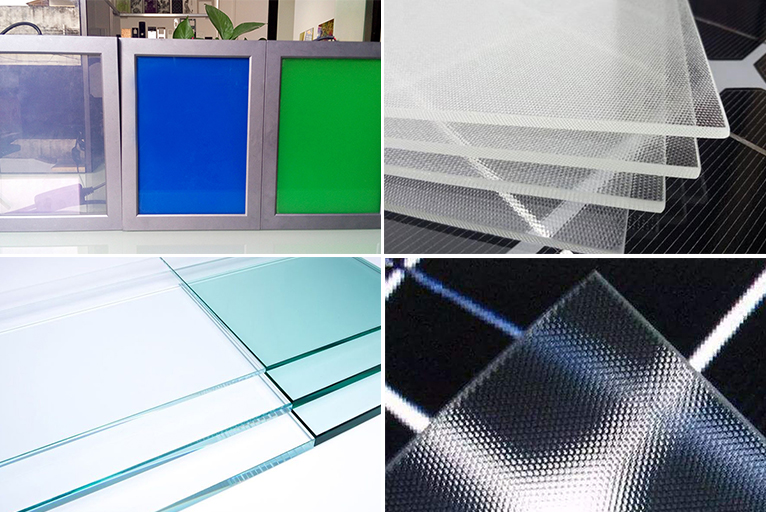

3. Glass coating (electrochromic, anti-reflection coating, solar glass, etc.)

The ultrasonic spraying machine can spray very thin nano-layers of anti-stain and other protective materials on glass of any width without dripping or bouncing. As the glass industry evolves, including the chemical composition of TCO and conductive coatings on glass panels, YMUS Ultrasound will continue to provide innovative ultrasonic coating solutions to manufacturers worldwide.

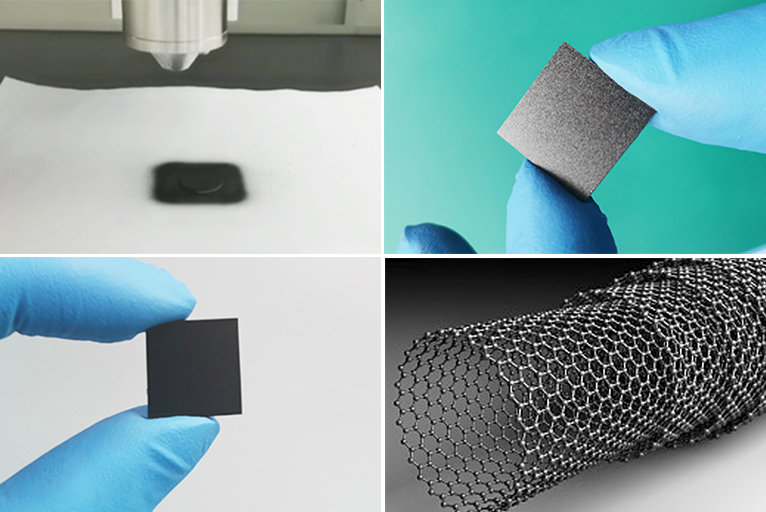

4. Nanomaterials (graphene, nanosuspension, carbon nanotubes, etc.)

Nano coating is a rapidly developing field of ultrasonic spraying technology. Ultrasonic spraying is very suitable for deposition of nano-coatings and is increasingly used in the development and production of spraying processes. Ultrasonic spraying technology can be used to deposit uniform nanocoatings on substrates of any width. Ultrasonic spraying technology enables the manufacture of these very thin coatings with extremely high uniformity, even over a very wide range, for unique nanoapplications.

5. Biomedical treatment (balloon catheter, medical stent, syringe, etc.)

Ultrasonic nozzles are particularly suited for a variety of medical coating applications due to their precision, non-blocking, repeatable spray performance and extremely low flow rate capability. For several years now, Ultrasound has been supplying ultrasonic spraying equipment to medical device manufacturers worldwide. With the development of medical device technology, we will continue to design unique ultrasonic spraying solutions for medical coatings and provide the highest quality medical device coatings in the market.

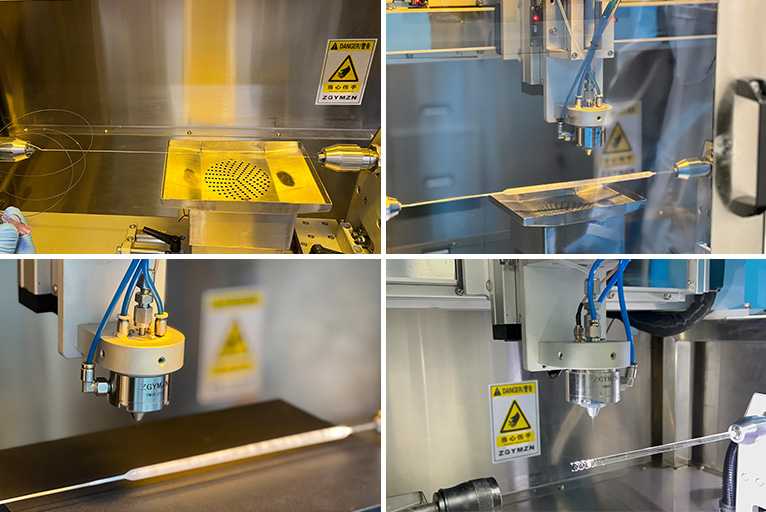

Ⅱ.Ultrasonic nozzle

YMUS ultrasonic atomizing nozzle is the use of ultrasonic energy to atomize water or liquid, forming a few μm to more than 100 μm size of tiny particles. Different from the traditional spray head which relies on pressure and high speed motion to crush liquid into small particles, ultrasonic spray head uses lower ultrasonic vibration energy to atomize liquid. Liquid can be transferred to the spray head by its own gravity or low pressure liquid pump and achieve continuous or intermittent atomization.