google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

5G material with excellent performance -- polymer material -- YMUS ultrasonic spraying

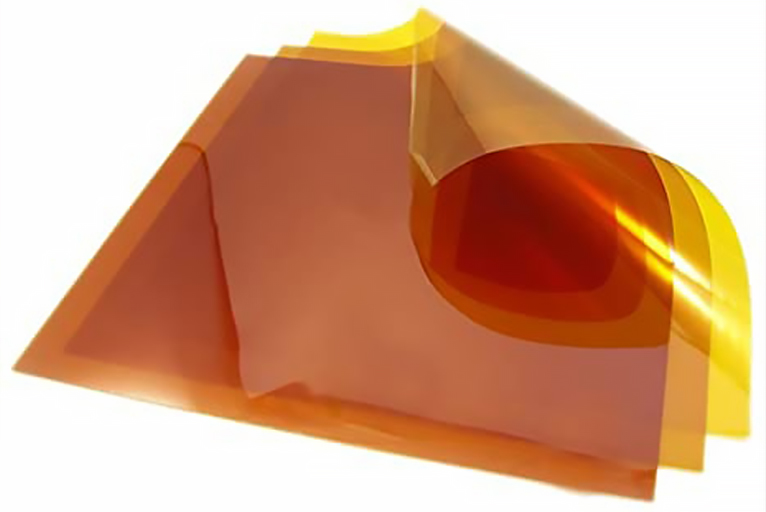

2019 has been called "the first year of 5G commercial use", and new materials suitable for 5G and the new era are also emerging. Developed the ultra-heat-resistant polyamide film "Pixeo SR" for the flexible circuit board of 5G smart phones, a PI film material with low transmission loss in 5G high frequency band, good adhesion to copper foil and excellent processing performance. Its dielectric loss is as low as 0.001(20GHz), with excellent heat resistance, mechanical properties, bonding properties and low dielectric loss properties, which can be applied to 5G communication and millimeter-wave radar components.

The invention relates to a PI film preparation method

A series of polyimide/molecular sieve composite films were prepared by adding silane coupling agent and ultrasonic dispersing molecular sieve into polysiloxane amidic acid copolymer solution for mixing and thermalimide.

In this study, by embedding dimethylpolysiloxane chain segment in BPDA/ODA molecular chain structure, using the characteristics of hydrophobic dimethylpolysiloxane chain segment and long chain molecular structure, reduce the water absorption rate and imide bond stacking density of PI film, and give polyimide film lower dielectric constant and dielectric loss. At the same time, the molecular sieve containing nano-holes was doped in the process of resin synthesis, so that the film finally has the characteristics of low dielectric constant and low dielectric loss. The selected molecular sieve requires small particle size to reduce the roughness of the film after filling the molecular sieve; High porosity is beneficial to introduce more air with low dielectric constant in the film. Small hole size, prevent resin infiltration in the hole, resulting in reduced air content.

PI film forming process

The solution is sprayed onto the surface of the substrate to form a continuous coating. After drying, the solvent contained in the coating is volatilized, and finally the film layer is formed. PI film with good transparency can be prepared.

PI film application field

1, insulation materials: motor, nuclear power equipment insulation, high temperature resistance wire and cable, electromagnetic wire, high temperature resistance wire, high temperature resistance pressure sensitive tape, insulation composite materials.

2. Semiconductor and microelectronics: passivation layer and buffer inner coating of microelectronics devices, interlayer dielectric material of multi-layer metal interconnecting circuit, photoelectric printed circuit board substrate.

3, electronic label: printed circuit board of the host board, corrosion products, mobile phones and lithium batteries.

4. Solar cell: transparent PI film is used as a soft solar cell bottom plate. Ultra-thin PI film can be applied with solar sail.

5, flexible circuit board: electronic grade PI film for electronic industry, information industry and a variety of defense industry with FPC.