google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

In situ preparation of quantum dot optical films——film spraying——Shanghai Yangmi ultrasonic spraying

Compared with conventional thin film systems, QD films have unique physical and chemical properties, such as adjustable band gap and band edge position, surface functionalization achieved by surface chemical modification, and high quantum efficiency caused by multiple exciton effects. The simple and flexible preparation technology and excellent physical and chemical properties make the thin films of quantum dots have high research value and great application potential in the field of photovoltaic devices.

Preparation process:

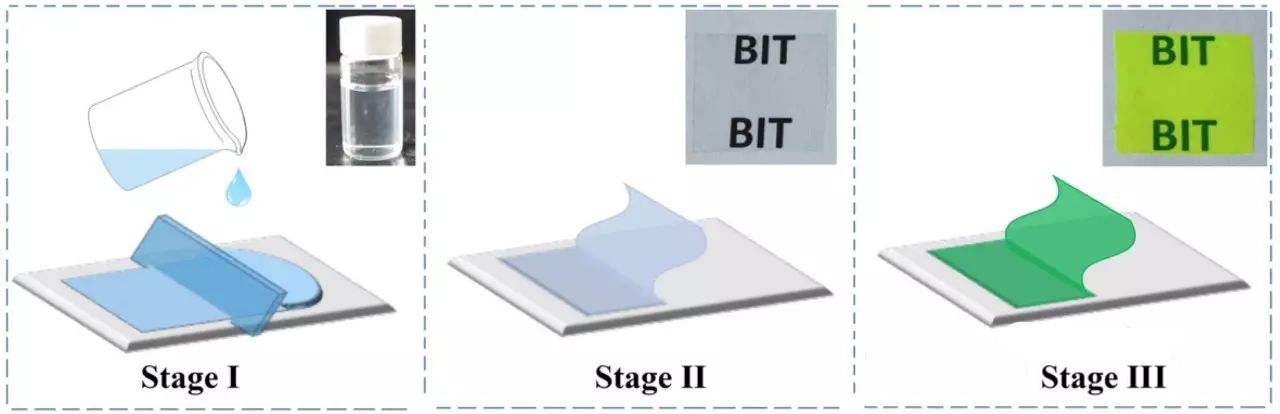

The preparation process of perovskite quantum dot optical film is mainly divided into three stages: the first stage is to prepare the precursor film forming solution containing PVDF matrix, perovskite material and organic solvent, and coating on the corresponding substrate; In the second stage, the coated wet film is placed in a vacuum drying oven. With the rapid evaporation of the organic solvent, the PVDF matrix crystallizes and forms a colorless transparent film. In the third stage, with the further volatilization of the residual organic solvent, the perovskite component reaches the critical nucleation concentration, and the nucleation and growth of the perovskite component are completed quickly, and the film gradually changes into a green transparent shape.

In situ preparation strategy process flow chart

Application Effect:

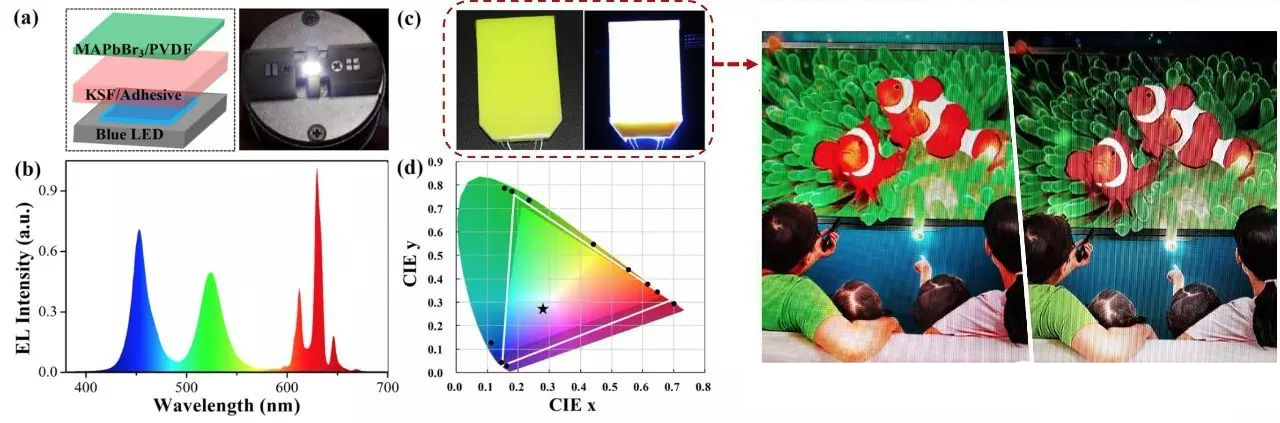

On the basis of material preparation, the application of perovskite quantum dot optical film backlight display is demonstrated. Firstly, the On-chip method was used to integrate the perovskite quantum dot optical film into the patch LED. The obtained white LED light source color coordinate (0.272, 0.278), color gamut 121%NTSC, luminous efficiency 109 lm/W, and the comprehensive index was the reported optimal value of quantum dot LED device. This shows the application advantage of perovskite quantum dot optical film in backlight. Subsequently, the perovskite quantum dot optical film is directly integrated into the backlight module of LCD by On-surface method, which fully demonstrates the great potential of perovskite quantum dot optical film in improving the color gamut of display devices. The color display effect comparison is shown in the figure below.

Application Display

ULTRASONIC CHINA

Our ultrasonic spray preparation solutions are used in fuel cell proton exchange film spraying, thin film solar cells, perovskite, microelectronics, semiconductors, nano-new materials, glass coating, biomedical, textile and other fields. Provide products, services and solutions that are more suitable for you and can be effectively applied to your industry area.

Ultrasonic precision spraying equipment