google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Wafer film deposition——Semiconductor spraying——Shanghai Yangmi ultrasonic spraying

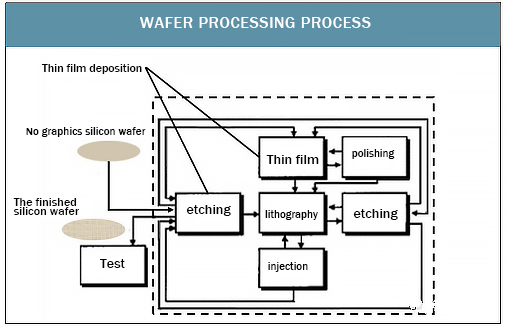

Thin film deposition is one of the key processes in wafer processing, which is mainly divided into physical vapor deposition PVD and chemical vapor deposition CVD. No chemical reaction takes place in the process of physical vapor deposition, but only physical changes such as phase transformation of substances. For example, the evaporation process is a process in which the solid evaporation source is converted into gas and a solid film is formed on the surface of the target. CVD, on the other hand, is carried out by chemical reaction. The reaction source is passed into the reaction chamber in the form of gas, and the target product is deposited on the substrate after chemical reaction with other external reactants or substrate.

Wafer processing process

Lithography is a major process in the production of planar transistors and integrated circuits. A processing technique in which the masking material (e.g. silica) on the surface of a semiconductor wafer is perforated to allow localized diffusion of impurities. The general lithography process has to go through the silicon wafer surface cleaning and drying, coating substrate, spraying photoresist, soft drying, alignment exposure, post drying, development, hard drying, etching, detection and other processes.

As we all know, chip manufacturing requires a variety of equipment, such as photolithography machine, etching machine, spraying machine, plasma injection machine, cleaning machine and so on. A wafer production line requires hundreds of kinds of equipment, and the equipment procurement cost accounts for 60% of the wafer construction cost. With the chip craze, a large number of enterprises are making cores, while the existing fabs are expanding production, requiring a large number of semiconductor equipment.

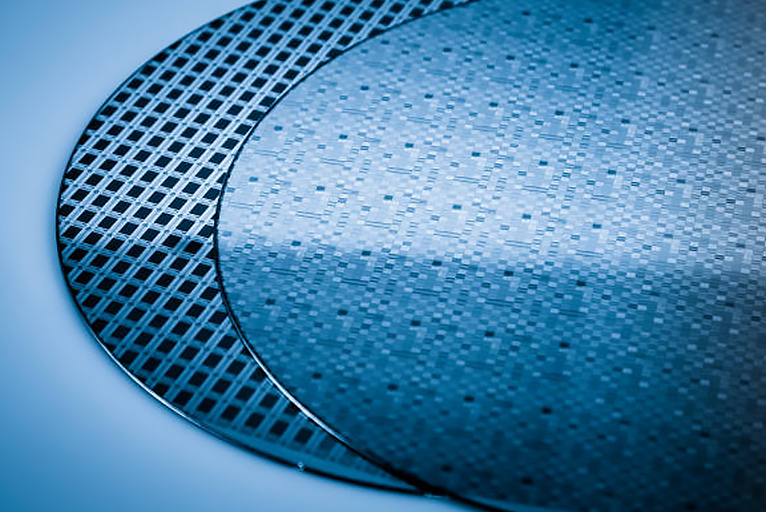

Semiconductor wafer

Shanghai Yangmi ultrasonic spraying

Ultrasonic spraying system, used in fuel cell proton exchange film spraying, thin film solar cells, perovskite, microelectronics, semiconductor, nano new materials, glass coating, biomedical, textile and other fields. Provide products, services and solutions that are more suitable for you and can be effectively applied to your industry area.

Ultrasonic precision spraying equipment

Shanghai Yangmi one-stop ultrasonic spraying application solutions, for the development of semiconductor industry to provide strong technical support.