google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic spraying for anti-reflection film - Solar cells - Ultrasonic spraying

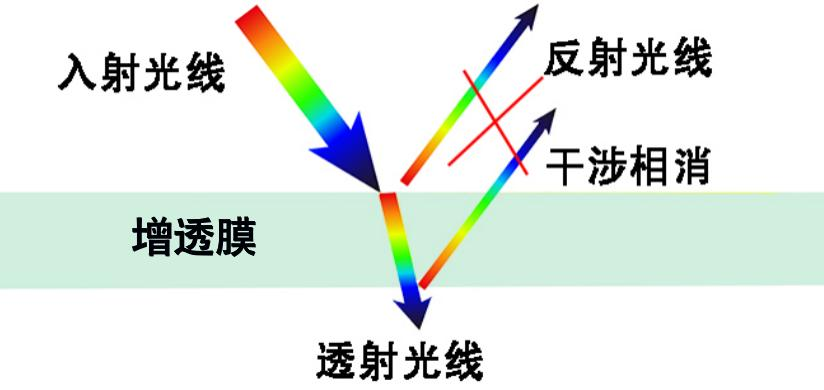

Glass is one of the most important photovoltaic materials in photovoltaic modules, and its reflection loss at the air/glass interface is about 4%. In order to further improve the transmittance of glass, a layer of anti-reflection film (ARC) is usually covered on its surface to improve the power and efficiency of the module. The principle is: sunlight will form different reflected light between different material interfaces, and the reflected light will interfere with each other to form new light waves. Due to the wave nature of light, there is a certain probability of superposition and cancellation, which weakens the reflected light and enhances the transmitted light. While the anti-reflection film plays an anti-transmission role, some film layers also have super hydrophobic and self-cleaning functions.

Anti-reflection film is also called anti-reflection film. Its main function is to reduce or eliminate the reflected light from optical surfaces such as lenses, prisms, and plane mirrors, thereby increasing the transmittance of these components and reducing or eliminating the stray light of the system. Photovoltaic anti-reflection coated glass is a cover glass applied to the surface of solar panels. Its main function is to protect crystalline silicon cells from damage by the external environment while ensuring the transmission of light.

The transmittance performance of anti-reflection coated glass directly affects the power generation of solar cells and determines how much light energy reaches the surface of the cell. Therefore, transmittance performance is one of the core indicators to measure its quality standards, so the preparation of anti-reflection film becomes a key link in the manufacture of photovoltaic modules. The use of ultrasonic spraying to prepare anti-reflection film can further enhance the transmittance of glass and improve the power and efficiency of photovoltaic modules.

YMUS ultrasonic spraying is a spraying method based on ultrasonic atomization nozzle technology. Ultrasonic spraying atomizes the solution and evenly falls on the solar cell module, preparing a nano-coating with higher uniformity, thinner coating thickness and higher coating precision, which improves the transmittance of glass and better protects solar modules.

Large-area ultrasonic precision spraying machine is a mass-production automatic ultrasonic spraying equipment, which can be equipped with wide-spray ultrasonic nozzles and can carry multiple nozzles to work in parallel at the same time. The automatic conveyor can automatically convey the samples, which is particularly suitable for mass-production and large-area thin film spraying. Such as fuel cell membrane electrode spraying, various glass coatings, thermal insulation film spraying, AR anti-reflection film spraying, photoresist spraying, transparent conductive film spraying, super hydrophobic coating spraying, etc.