google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

The ultra-high temperature pyrolytic spraying machine is a new type of spraying machine for preparing perovskite glass. Compared with the traditional sol-gel method, electroion sputtering and physical vapor deposition, the ultra-high temperature pyrolysis method has its unique advantages and advantages.

I. Efficient and stable synthesis of perovskite

By means of high temperature pyrolysis, perovskite material is sprayed on glass matrix to form uniform and highly stable perovskite film. Compared with traditional methods, this method can produce more symmetrical and stable perovskite materials in a shorter time. At the same time, the ultra-high temperature pyrolysis spraying machine has the advantages of simple structure and convenient operation, which can effectively improve the working efficiency and reduce the production cost.

Ⅱ. Better quality perovskite film

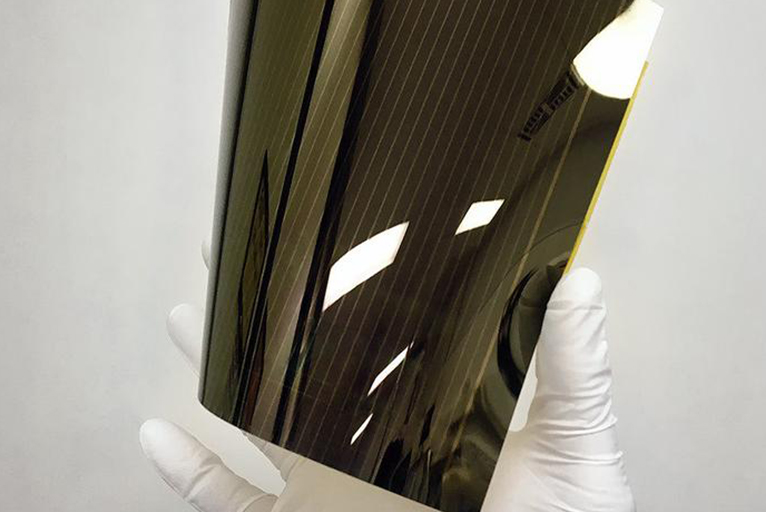

The perovskite materials sprayed by ultra-high temperature pyrolytic spraying machine have better physical properties, including higher light absorption and photoelectric conversion efficiency. This is because the method can make perovskite materials under the influence of high temperature in the preparation process, so that the crystal structure is more ordered, and the same thickness of perovskite films have better optical properties.

Ⅲ. A wider range of applications

The ultra-high temperature pyrolytic spraying machine is not only suitable for preparing perovskite glass, but also for spraying various materials and compounds. The advantage of this spraying method is that the film produced has extremely high physical properties, mechanical strength and heat resistance, and is suitable for the manufacture of LED, solar cells, flexible displays and other electronic products. At the same time, the method has low production cost and high efficiency, which can play an important role in future application scenarios.

Ultra-high temperature pyrolysis spraying machinery has the advantages of low production cost, high efficiency, and excellent physical properties, mechanical strength and heat resistance of the film produced. In the future application, it will play a more important role in LED, solar cell, flexible display and other fields.

YMUS-ZM200HT ultra high temperature film preparation ultrasonic spraying machine, the first ultra high temperature pyrolysis spraying machine in China. The utility model relates to a small ultrasonic spraying equipment, which can be equipped with a gathering type ultrasonic nozzle, a wide spray type ultrasonic nozzle or a scattering type ultrasonic nozzle, especially suitable for research and development and small area film spraying. Such as fuel cell membrane electrode spraying, thin film solar cell spraying, semiconductor photoresist spraying, transparent conductive film spraying, etc. 750℃ hot table can be configured with microporous vacuum heating, suitable for battery diaphragm and other flexible substrates.