google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic atomization spraying technology to help high-end spraying demand -- Atomization spraying -- YMUS ultrasonic spraying

Due to the emergence of new applications and new materials, the traditional processing technology is faced with problems such as insufficient processing precision and easy destruction of antibacterial properties of coatings. The upgrade of ultrasonic atomization spraying technology ensures the stability of antibacterial coating, strong application performance to meet the needs of high-precision spraying, is becoming more and more high-end industry's first choice.

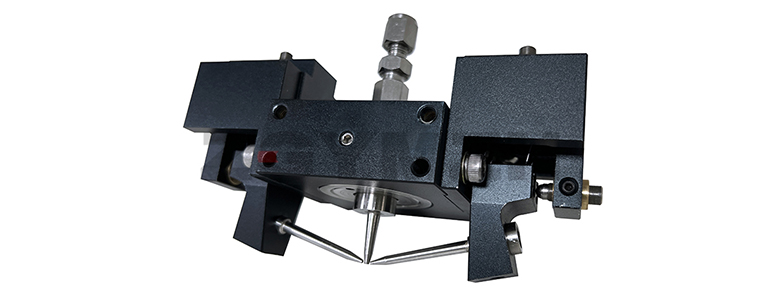

Note:YMUS ultrasonic atomizing nozzle series

What is ultrasonic atomization spraying technology?

Ultrasonic atomization is the use of electronic high-frequency oscillation (oscillation frequency is 1.7MHz or 2.4MHz, beyond the range of human hearing, the electronic oscillation is harmless to human body and animals), through the high frequency resonance of ceramic atomization plate, the molecules between liquid water molecules will be dispersed to produce natural and flowing water mist. It can reach atomized particle sizes of 10 microns or less, known as "dry fog." Without heating or adding any chemical reagents, the stability and performance of the coating can be maintained to the greatest extent. Compared with heating atomization, the energy is saved by 90%.

Widely used

In practical application, atomization technology can be used for humidification, dust removal, cleaning and other needs. Due to the advantages of ultrasonic atomization technology, such as high precision, uniform spraying, small impact on solution performance and high conversion rate for expensive solution, it is suitable for new energy, biomedicine, microelectronics semiconductor, nanomaterials, glass coating and other fields.

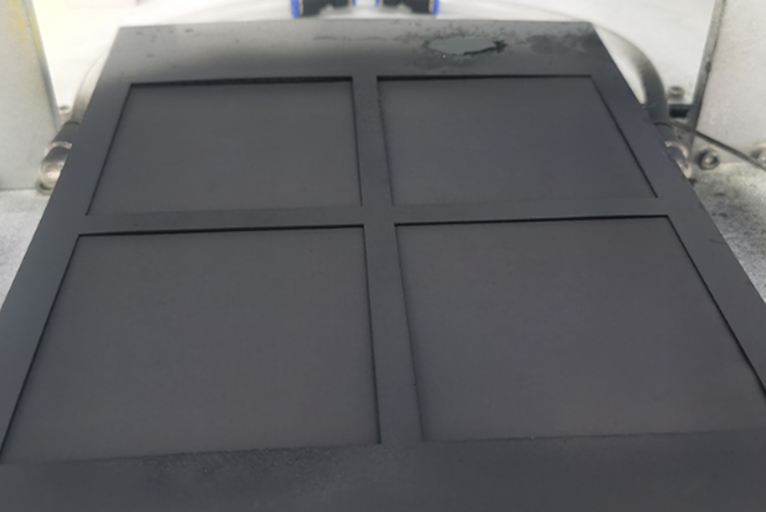

Ⅰ. Battery coating for new energy vehicles

Ultrasonic spraying technology is ideal for painting expensive materials, such as platinum and other precision metals, in carbon black ink pastes. When applied to fuel cells using ultrasonic nozzles, these chemicals perform chemically superior to hydraulic deposition, pressing, blade and paste printing methods. Therefore, ultrasonic spraying technology has been used in many fuel cell related production and processing, such as proton exchange membrane (PEM) fuel cells, gas diffusion layer (GDL), solid oxide fuel cells, electrodes and electrolyte membranes.

Note:Proton exchange membrane

Ⅱ. Medical devices

Due to the ultra-low flow rate and low speed soft spraying characteristics, ultrasonic spraying method is very suitable for coating on complex, small, three-dimensional objects and other structures. Such as drug eluting stent, drug eluting balloon, guide wire, sea wave tube, catheter, mandrel, etc. In addition, ultrasonic spraying can replace the traditional dip coating method for parts such as wire, conduit and sea wave tube, thereby reducing waste and improving concentricity and longitudinal uniformity.

Note:YMUS-X Small area spraying

Ⅲ. Conductive coating

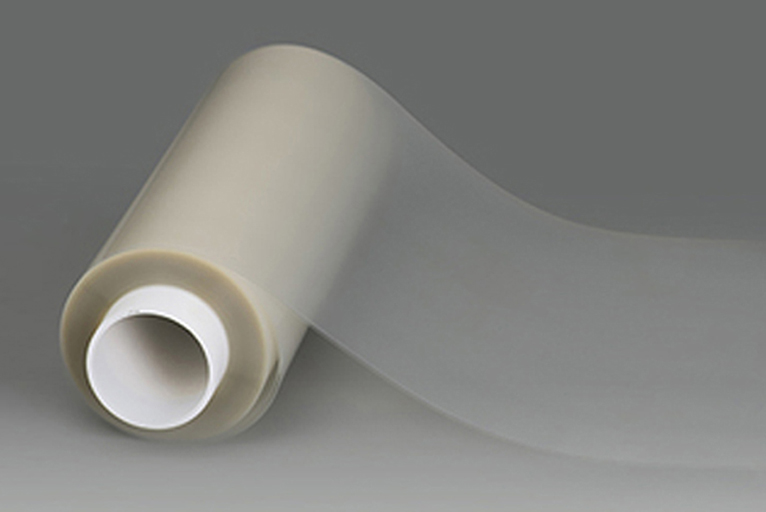

Indium tin oxide (ITO) has excellent transparency and low thin layer resistance, but it is a scarce material and easy to crack, so it is not suitable for the new flexible transparent conductive film (TCF). Using graphene, make flexible films that conduct electricity and are transparent. Silver nanowires (AgNWs) are superior TCF substitutes to ITO when combined with graphene. Ultrasonic spraying technology is adopted to meet the requirements of flexibility.

Note:Conductive thin film

Conclusion

Ultrasonic atomization technology is a high-end precision spraying process that controls the movement of the nozzle or substrate to obtain a uniform coating. Precise spraying of small and complex structures without damaging the function of the coating. YMUS ultrasonic spraying system will meet the needs of more spraying process.