google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic precision spraying technology: Preparation of better perovskite solar cells - Solar - YMUS ultrasonic spraying

An ultrasonic precision spraying method realizes complex perovskite solar cell design and can be used in mass production.

Perovskite is a kind of semiconductor material which arouses great interest of scientists all over the world. Its crystal structure is unique, with excellent optical and electronic properties.

Perovskite's structure is ideal for use as an active layer to absorb light in solar cells because it absorbs light more efficiently than silicon and costs less. Over the past decade, perovskite has emerged as an alternative to silicon solar cells because it is cheaper and greener to make and is comparable in efficiency.

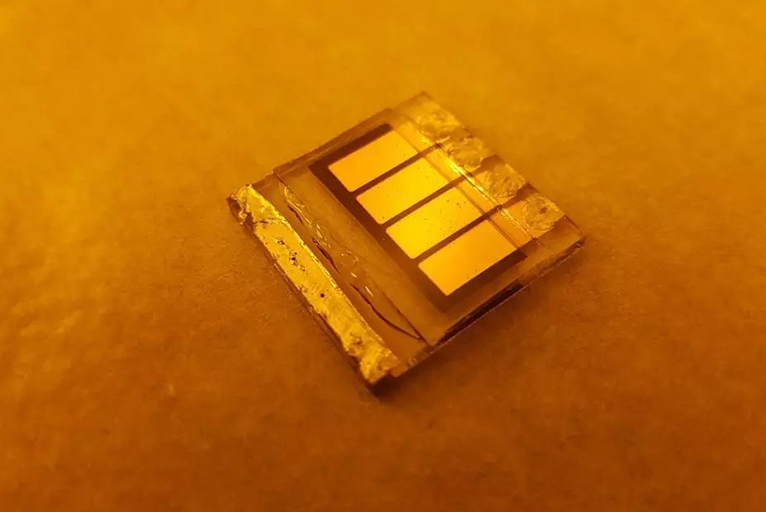

Perovskite Solar (photo credit: UNIST)

Perovskites are promising for a new generation of solar cells because they absorb light and convert it into electricity with greater efficiency and lower production costs than silicon. Perovskite can even be sprayed onto glass to create energy-generating Windows.

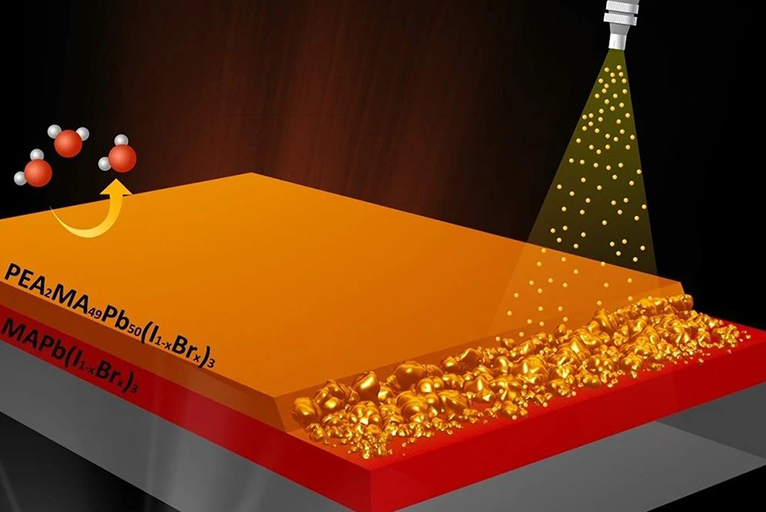

Ultrasonic spraying demonstrates the process of depositing perovskite layer by layer, and the thickness and deposition rate of each layer are precisely controllable, thus achieving better performance and stability for the stacking design of solar cells. Each layer coated with a different perovskite material can customize the function of the device or meet specific performance and stability requirements.

One advantage of perovskite is that it can be processed in solution, meaning that solar cells are made by drying liquid perovskite into a solid at low temperatures. The manufacturing process is much simpler than making traditional silicon solar cells.

Through the ultrasonic spraying process, the upper layer of solution does not affect the solid film that makes up the first layer. By precisely controlling the thickness and deposition rate of each layer, we can design and create endless combinations of stacked perovskite architectures with any number of layers.

YMUS ultrasonic spraying process a perovskite material with higher stability is deposited onto another perovskite material with better electrical properties, achieving higher performance and good stability. Multilayer perovskite devices with new functional properties and stability were prepared.