google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Breakthrough in SiC growth core material - third generation semiconductor - YMUS ultrasonic spraying

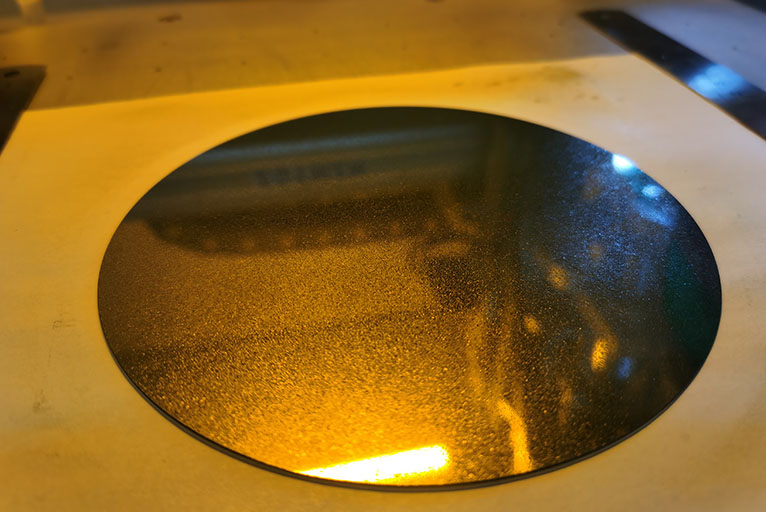

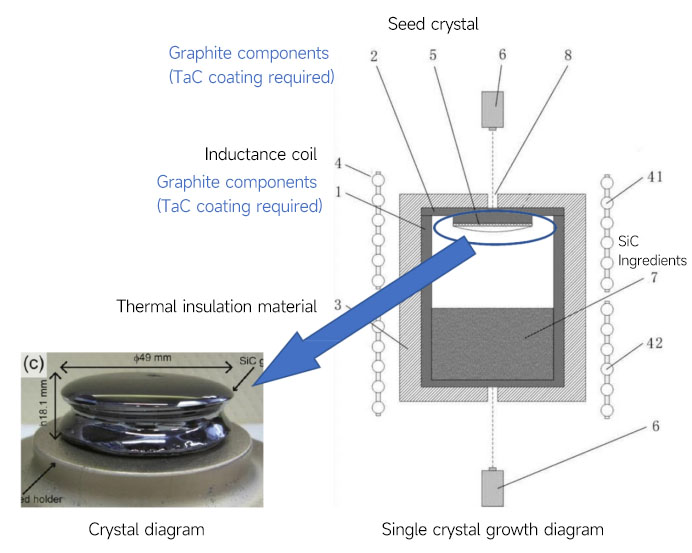

TaC ceramics have a melting point of up to 3880℃, high hardness (Mohs hardness 9 ~ 10), large thermal conductivity (22W·m-1·K−1), large bending strength (340 ~ 400MPa), and small thermal expansion coefficient (6.6×10−6K−1), and show excellent thermochemical stability and excellent physical properties. It has good chemical and mechanical compatibility with graphite and C/C composite materials, so TaC coating is widely used in aerospace thermal protection, single crystal growth, energy electronics, and medical devices. TaC coated graphite has better chemical corrosion resistance than bare stone ink or SiC coated graphite, can be stably used at 2600° high temperature, and does not react with many metal elements, is the best performance of the third generation semiconductor single crystal growth and wafer etching scene coating, can significantly improve the control of temperature and impurities during the process. Preparation of high quality silicon carbide wafers and related epitaxial wafers. It is especially suitable for growing GaN or AlN single crystal in MOCVD equipment and SiC single crystal in PVT equipment, and the quality of the single crystal grown is obviously improved.

The liquid tantalum carbide is adhered to the cemented carbide substrate by ultrasonic spraying. Under the action of ultrasonic high-frequency vibration, dispersion is generated inside the liquid particles, and the liquid particles are precisely atomized. After many spraying, drying, calcination and other technological steps, the tantalum carbide coating with certain thickness, quality, structure and composition is finally formed. Finally, through inspection, testing and analysis, confirm whether the tantalum carbide coating meets the design requirements or process indicators, and evaluate the performance and application performance of tantalum carbide coating.

The tantalum carbide coating prepared by YMUS ultrasonic spraying has the advantages of high production efficiency, low cost and simple operation. At the same time, the prepared tantalum carbide coating has the advantages of high density, high hardness and wear resistance, which plays an important role in improving the performance and surface quality of cemented carbide substrate.