google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Nitinol stent surface coating process -- Medical equipment -- YMUS ultrasonic spraying

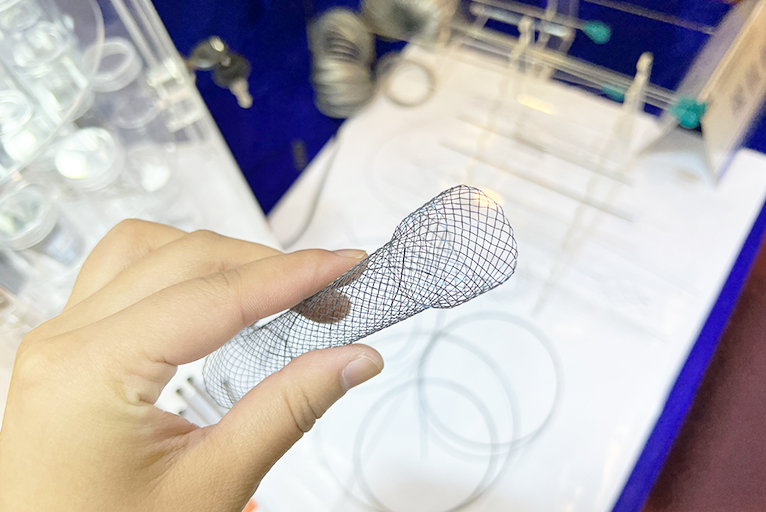

Cerebrovascular etiology, with its high rate of disability, recurrence and mortality, has become the second leading cause of death in humans, after ischemic heart disease. In interventional therapy, implant devices can be roughly divided into four subtypes, namely embolization device (spring coil), stent, shunt device and stent thrombectomy device. Stent implantation plays an important role in the treatment of ischemic cerebrovascular diseases (carotid artery stenosis, unilateral artery stenosis, bilateral artery stenosis, etc.). The selection of a suitable stent depends on the implant site, the extent of the lesion, the stent material, plaque complexity, and vascular anatomical assessment, as well as the expertise of the surgical physician. To this end, many scholars use ion implantation, ultrasonic spraying, pulsed laser deposition, physical or chemical vapor deposition, sol-gel wet chemistry, electrodeposition and surface texture electropolishing technology to modify the metal surface to improve the biological characteristics of implant materials.

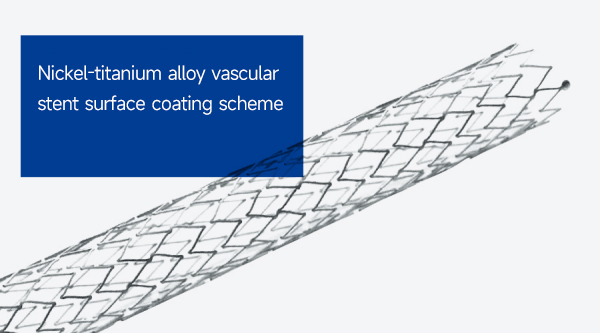

Due to the chemical inertia of nickel/titanium, nitinol (NiTi) is prone to forming a dense oxide layer with a thickness of 2 to 20 nm, which grows and absorbs minerals (such as calcium phosphate) and other components of biological fluids during implantation, resulting in surface remodeling that gives it good corrosion resistance. In order to improve the biocompatibility and corrosion resistance of NiTi alloy implants, targeted surface modification is essential. Depending on the surface treatment of the stent, NiTi vascular stents can be divided into bare type, coated type and coated type. The surface of the bare scaffold is only polished to achieve the ultimate smooth surface, improve the hydrophilicity, and its hydrophilic surface is conducive to the growth of endothelial cells, greatly reducing the probability of secondary damage to vascular endothelium caused by stent implantation. The coating type is coated with substances containing vascular endothelial growth factor and heparin on the metal surface to stimulate the migration and proliferation of microvascular endothelial cells and regulate the permeability of the blood vessel wall through surface slow release. Coated type, that is, coated with degradable or non-degradable polymer film on the surface of the metal stent, so that it can isolate the vascular lesion site, interrupt the blood supply here, and form a new blood flow channel, so as to achieve the purpose of treatment.

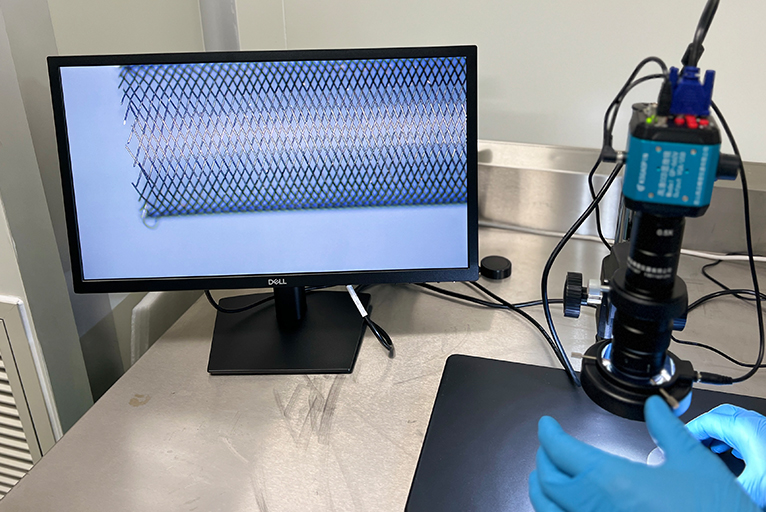

Coated stents usually use polymers as the substrate layer or spray drugs directly onto the surface of the stent. Different coating components will have different release and absorption kinetics, indicating that different coatings may affect the clinical outcome by affecting the process of injury healing and repair after stent implantation. The YMUS-ZJ100 ultrasonic spraying equipment is used to obtain a smooth surface with good viscosity and inertia. The coating has better biocompatibility and stability than other samples.

Due to the thickness and uniformity of the drug-carrying polymer coating, the speed and duration of drug release and the coverage of the drug on the surface of the lesion site are greatly affected. Therefore, efficient and accurate preparation techniques for surface coatings are required.

At present, the commonly used measurement methods for the thickness and surface distribution of drug coatings are:

1, the method of controlling the number and time of spraying roughly calculates the thickness of the drug coating.

2, with the scanning electron microscope ruler to measure the film thickness and confirm the distribution.