google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Translucent perovskite solar cells -- Thin film preparation -- YMUS Ultrasonic spraying

In order to achieve translucent perovskite solar cells with high efficiency, high stability and high light transmittance, it is necessary to improve the quality of perovskite thin film crystal on the one hand, and improve the light transmittance of perovskite devices on the other hand. Therefore, the preparation of high quality perovskite film and transparent electrode are very important.

For translucent perovskite solar cells, due to its high requirements for light transmittance and band gap adjustment flexibility, it is inevitable that translucent cells will deteriorate the film quality due to various factors and reduce the comprehensive performance of devices under the premise of meeting the above requirements. Therefore, how to learn from and improve the traditional perovskite solar cell preparation method to prepare high quality perovskite thin film is particularly critical.

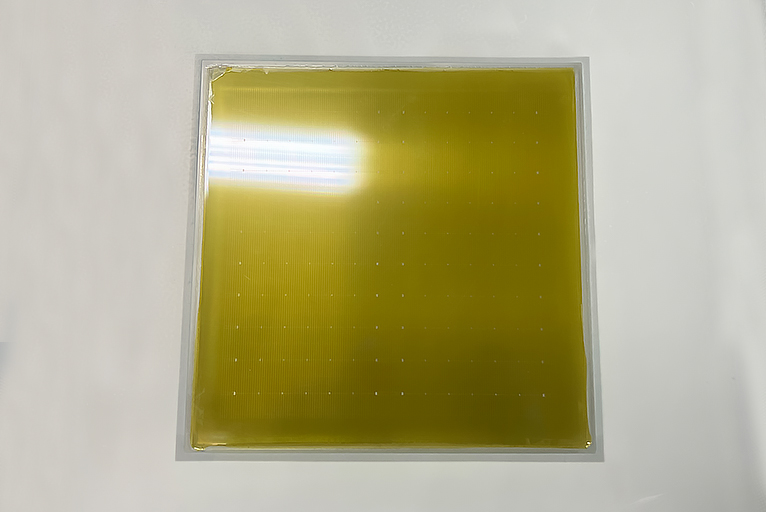

With the gradual commercialization of perovskite solar cells and the demand characteristics of translucent perovskite solar cells in multiple application scenarios, the drawbacks of solution spin coating method in large area preparation difficulties, film consistency is insufficient and other aspects are gradually emerging. Therefore, a method for preparing large area perovskite solar cells by ultrasonic spraying has attracted wide attention in recent years.

YMUS ultrasonic spraying equipment can be prepared from experimental type to mass production, transmitted to atomizing nozzle through YMUS ultrasonic dispersing syringe, and atomized into micron-scale tiny droplets through high-frequency vibration in the nozzle. Under compressed air, tiny droplets are deposited evenly on the substrate. The droplets remain below the nozzle and coalesce to form an ultra-thin, wet coating film.

YMUS Ultrasonic spraying equipment can coat nanoscale films, spraying uniformity up to 95%, an automatic spraying equipment to provide uniform and efficient film spraying.