google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

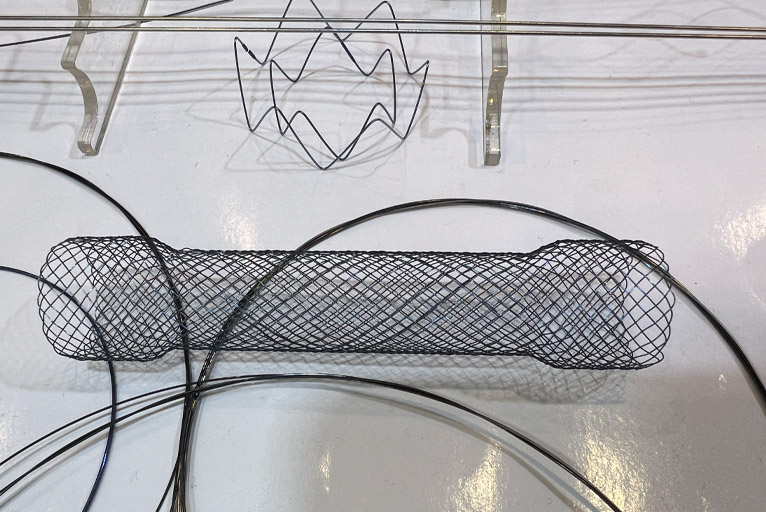

Esophageal stents are important medical devices for the treatment of esophageal stenosis, fistulas and malignant tumor obstruction. Their surface properties directly affect the clinical effect. Traditional stent materials (such as metals or high molecular polymers) are prone to tissue inflammation, bacterial adhesion and restenosis risks. In recent years, the ultra-thin film coating technology based on Parylene has achieved functional modification of the stent surface through ultrasonic spraying process, providing a new idea for improving the biocompatibility and long-term efficacy of the stent.

Advantages of Ultrasonic Spraying Technology

1. High uniformity and consistency

Ultrasonic spraying technology can atomize the parylene solution into tiny droplets of uniform size, thereby forming a uniform coating on the surface of the esophageal stent. Compared with traditional spraying technology, ultrasonic spraying can significantly reduce the thickness difference of the coating, avoid the phenomenon of local over-thickness or over-thinness, and thus improve the quality and consistency of the coating.

2. Efficient use of materials

Since ultrasonic spraying technology can accurately control the size and distribution of droplets, it can minimize material waste. As an expensive medical polymer material, the efficient use of parylene not only reduces production costs, but also reduces the impact on the environment.

3. Adjustable coating thickness

By adjusting the parameters of ultrasonic spraying (such as frequency, flow rate, spraying time, etc.), the thickness of the coating can be precisely controlled. This is particularly important for esophageal stent coatings, because too thick a coating may affect the flexibility of the stent, while too thin a coating may not provide adequate protection.

Process optimization and challenges

Key process parameters

● The purity of the precursor (parylene monomer) must be ≥99.9% to avoid inflammation caused by impurities.

● The humidity of the spraying environment must be controlled (<20% RH) to prevent hydrolysis of the coating.

● The post-curing temperature (120-150℃) affects the cross-linking degree and mechanical strength of the coating.

● Uniform coating of complex structure scaffolds (such as multi-segment or barbed designs).

Ultrasonic spraying parylene technology provides a reliable solution for upgrading the performance of esophageal stents by precisely controlling the coating structure and function. With the advancement of materials science and micro-nano processing technology, this technology is expected to be more widely used in cardiovascular stents, artificial joints and other fields, and promote the development of biomedical materials in the direction of "intelligent bionics".