google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

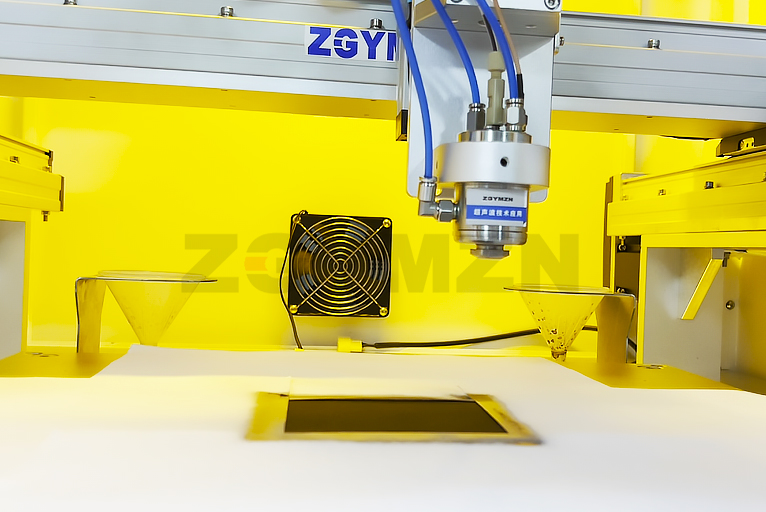

Metal oxide nanoparticles deposition——Ultrasonic coating——Shanghai ultrasonic spraying

Nanocoatings are coatings or thin films on solid surfaces. They play an important role in changing surface properties such as hydrophobicity, durability, and reactivity. Nanocoatings can be applied to the surface of various technologies, including gas and liquid phases. In contrast to gas-phase techniques, liquid-phase coatings do not require complex and expensive tools. A widely used liquid process is ultrasonic coating technology. The ultrasonic coating system is particularly suitable for spraying nano-suspended substances, such as carbon nanotubes, nanowires, perovskite, graphene, etc.

Application of ultrasonic coating:

Carbon nanotubes and nanowires are deposited in uniform, extremely thin coatings to replace existing energy, electronics, semiconductor or medical applications

Spray catalyst inks in fuel cell manufacturing

The solar cell substrate is coated with active chemicals containing metal oxides

An anti-reflective coating on solar glass

An antifouling or other protective coating on float glass

Shanghai Yangmi ultrasonic spraying system, used in fuel cell proton exchange membrane spraying, thin film solar cells, perovskite, microelectronics, semiconductor, nano new materials, glass coating, biomedical, textile and other fields. We can provide you with more suitable products, services and solutions, which can be effectively applied to your industry area.